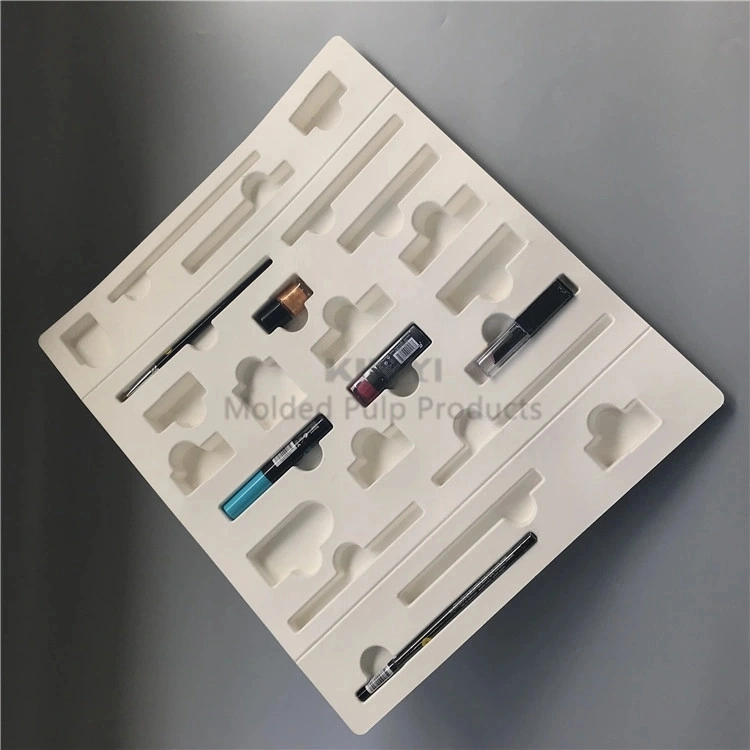

Non Plastic Eco Friendly Biodegradable Pulp Insert for Making Molded Package

Overview Product Description KINYI-A professional manufacturer of molded pulp products which be made of eco friendly bio

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | KYYG-012 |

| Shape | Customized Shape |

| Thickness | Optional From 0.8mm-2mm |

| Weight | Based on Product |

| Sampling Time | 5-7 Days |

| Production Mold Time | 10-12 Days |

| Technique | Wet Press Pulp Molding/ Dry Press Pulp Molding |

| Printing Mode | Customized |

| Item Name | Packaging Tray |

| Logo&Design | Customized |

| OEM and ODM Service | Available |

| Nda Services | We Accept Nda |

| Payment | T/T; Western Union; Money Gram etc |

| Shipment | by Sea &Plane& Express |

| Printing | Silk Print &UV etc |

| Transport Package | Paper Carton+Poly Bag |

| Specification | Customized shape |

| Trademark | KINYI |

| Origin | Dong Guan City of China |

| HS Code | 482370 |

| Production Capacity | 5000 PCS/Day/Mold |

Product Description

KINYI-A professional manufacturer of molded pulp products which be made of eco friendly biodegradable materials,which can be widely used in electronics, cosmetics, food, medical industry, industrial line and many other industries.

| Item Name | Packaging Tray |

| Feather | ECO friendly biodegradable;Recycle; Effective; Brand Enhancing; Economic; High Quality |

Our Advantages

1).Ecofriendly Package: Our molded pulp products are ecofriendly, compostable, 100% recyclable and biodegradable;

2).Renewable Material: All the raw materials are natural fiber-based renewable resources;

3).Customized Color: The most common color is white, grey and brown, but can be customized in any color as per request;

4).Advanced technology: Product Can be made by different techniques to achieve different surface effects and price targets;

5).Design Shape: Shapes can be customized;

6).Protection Capability: Can be made water-proof, oil resistant and anti-static; they are anti-shock and protective;

7).Price Advantages: the prices of molded pulp materials are very stable; lower cost than EPS; lower assembly costs; Lower cost for storage as most of the products could be stackable.

8).Customized Design: We can provide free designs or develop products based on customers' designs.

Packaging & Shipping

Related Products

-

![Hot Selling Double PE Coated Paper Ice Cream Cups]()

Hot Selling Double PE Coated Paper Ice Cream Cups

-

![Customized Size Food Grade Disposable Kraft Paper Bowl for Fast Food Take Away Food Salad Cookies Fruits Vegetables]()

Customized Size Food Grade Disposable Kraft Paper Bowl for Fast Food Take Away Food Salad Cookies Fruits Vegetables

-

![Disposable Double Wall Paper Coffee Cup Drinking Cup Printed Paper Cup PLA Cup]()

Disposable Double Wall Paper Coffee Cup Drinking Cup Printed Paper Cup PLA Cup

-

![High Quality Custom Printed 4oz 7oz 8oz 10oz 12oz 16oz Double Wall Paper Coffee Cups with Lid]()

High Quality Custom Printed 4oz 7oz 8oz 10oz 12oz 16oz Double Wall Paper Coffee Cups with Lid